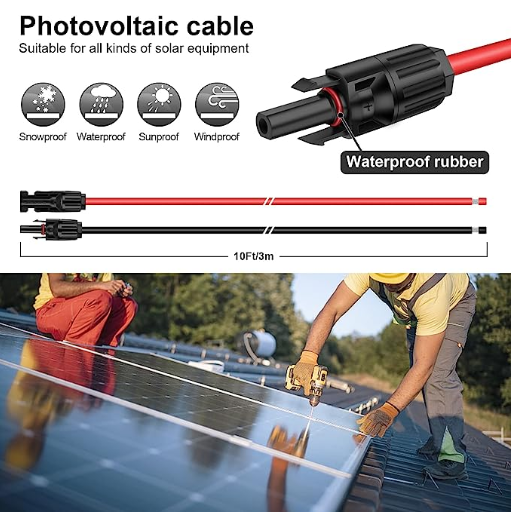

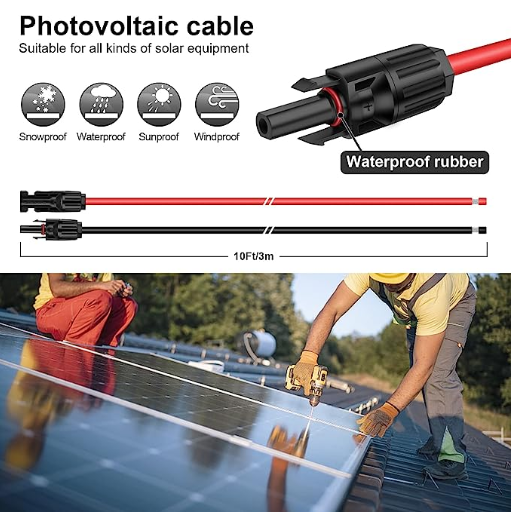

Wires & Cables for Photovoltaic and Solar ApplicationsSolar wire become popular products?

With the rise of new energy and the rapid development of the photovoltaic industry, solar photovoltaic lines have also become popular products.

But do you know anything about photovoltaic wire products?

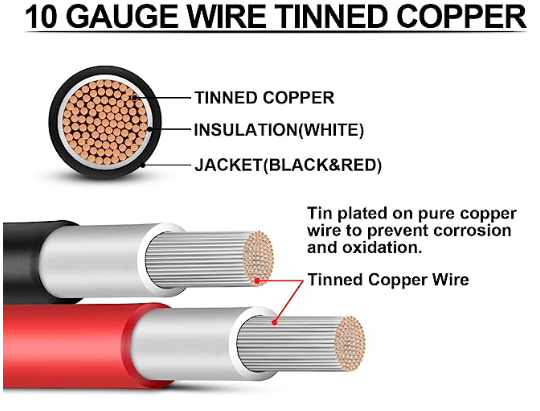

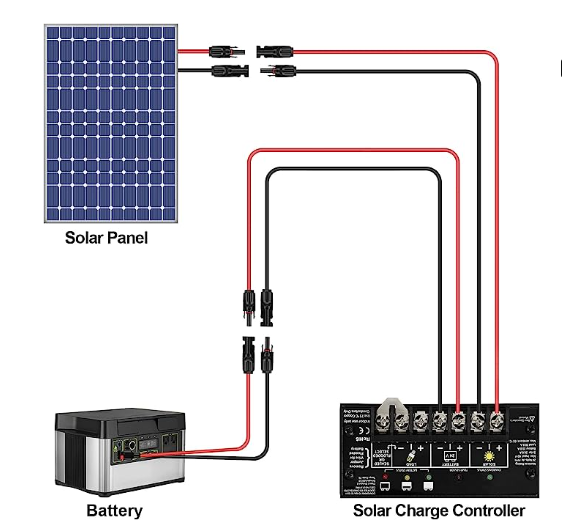

First of all, in terms of conductor material, both photovoltaic wires and household wires use conductors or tinned copper conductors, and there is not much difference between the two in this regard. Secondly, there is a big difference between the two in the insulating sheath. The photovoltaic wire uses the radiation cross-linked polyolefin insulating protective sheath. Generally, irradiated cross-linked polyolefin has strong environmental adaptability, chemical corrosion resistance, mechanical pull resistance and strong high temperature resistance, and the maximum rated temperature can reach 120°C.

The PVC sheath used by ordinary cables also has certain environmental tolerance, but it is not resistant to high temperature and low cold, so it is usually not suitable for outdoor use. Usually used for indoor wiring, it can exert a relatively stable effect, while photovoltaic cables usually need to be used in harsh outdoor environments.

The material of photovoltaic cables is generally considered from three aspects: conductor, insulation layer and sheath. Different materials can be selected according to different use environments and needs. The following are common photovoltaic cable materials:

- Conductor material: pure copper, copper-aluminum alloy, copper-nickel alloy, etc.;

- Insulation layer material: polyolefin, cross-linked polyethylene, silicone rubber, etc.;

- Sheath material: polyvinyl chloride (PVC), polyurethane, cross-linked polyolefin, etc.

Among them, copper is a common conductor material, which has good electrical and thermal conductivity, and can maintain a low resistivity even under the condition of thermal differentiation. The insulation layer of photovoltaic cables needs high temperature resistance, voltage resistance, fire resistance and flame retardancy. The sheath material needs to have the characteristics of weather resistance, chemical corrosion resistance, flame retardancy and wear resistance, so that the photovoltaic cable can operate stably for a long time in complex outdoor environments.

Since the repeated bending performance and strength of the solar cable stranded wire are better than that of a single conductor, the stranded wire is widely used in overhead lines, large-section power cables and home decoration laying. In the past, a single solid hard conductor was mostly used for home decoration wiring, mainly because of the price issue. Slightly lower than the multi-strand wire, the wiring is convenient and not easy to loosen. The connection of 7-strand wires can adopt the plug-in winding method, but the connection of 19 strands and more than 49 strands can only use the outer winding method. Wiring is rather cumbersome. Electrician practitioners or those who have connected the wires know that multi-strand wires such as BVR wires must be tinned after being connected, otherwise the connectors are easy to oxidize and loosen.

In terms of electrical performance, the “conductor resistance”, “skin effect”, “current carrying capacity” and other indicators of solar cables, what I want to say is that there is not much difference between single-core conductors and stranded conductors in the home. The skin effect is not obvious in power frequency AC, but if the cross section is large, the skin effect needs to be considered. For example, the steel-cored aluminum stranded wire used for high-voltage transmission lines has a steel core wire in its center, which does not affect the current in the outer aluminum conductor; the conductor resistance is not much different, but the stranded wire is made of multiple single wires after all. . Contact resistance occurs when there is a gap between the single wires. Therefore, the conductor resistance of the twisted wires of the same section of the solar cable is slightly greater than that of a single conductor; the current carrying capacity is no different. However, the heat dissipation of the twisted wire is better than that of a single wire, so the carrying capacity is slightly larger than that of a single wire.

Regarding the price of photovoltaic lines, the price varies from country to country. How much is your national photovoltaic line? leave your comment!