Photovoltaics丨What are epoxy resin and silicone encapsulation materials?

What is epoxy resin encapsulation material?

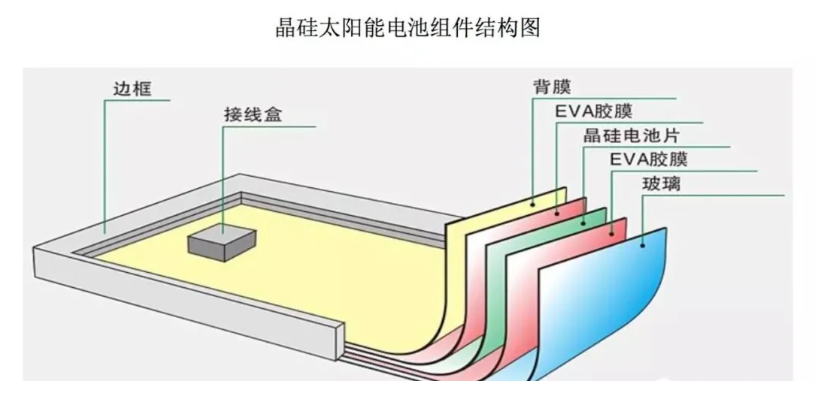

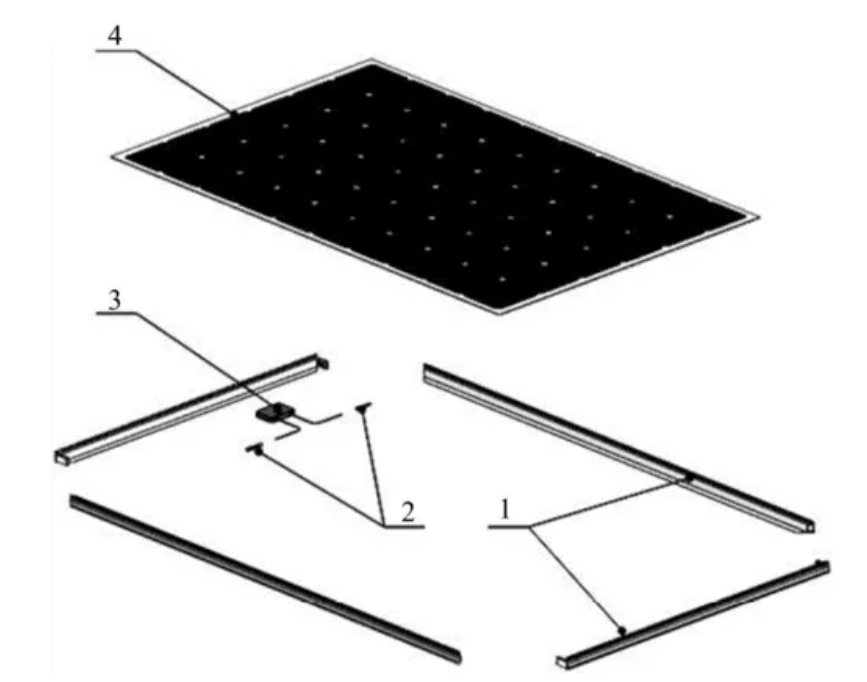

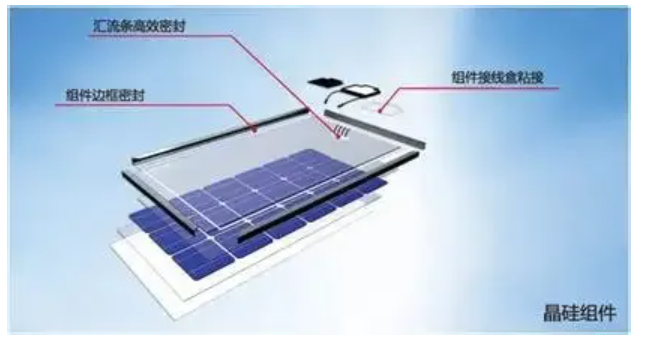

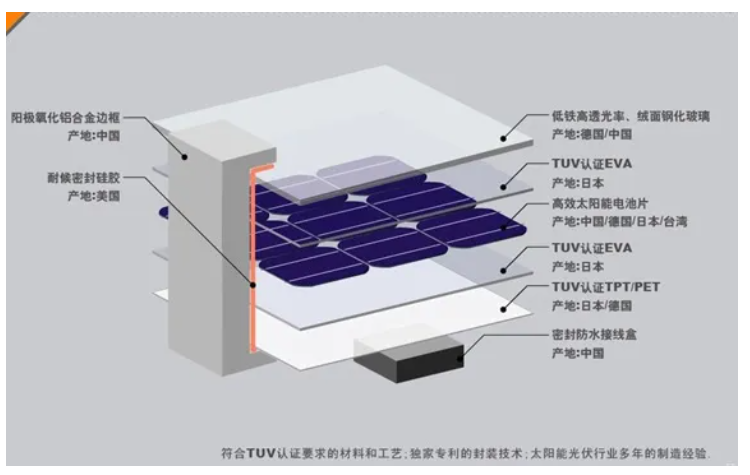

Solar cells generally have to be encapsulated into a flat plate structure through glue sealing, lamination, etc. before being put into use. Among them, the lamination encapsulation method is the most common.

The main materials used for vacuum lamination packaging of solar cells are epoxy resin, silicone resin, glass, EVA, Tedlar or Tedlar composite film, such as TPT (TPE), connecting strips, aluminum frames, etc. The characteristics of the packaging material have an important impact on the performance and service life of solar cell modules.

Epoxy resin is a relatively common adhesive, and its product forms are also diverse. It can be made into a single component or a two-component, or a powdered resin.

The epoxy resin adhesive used in solar cells is a two-component liquid that is prepared and used immediately. By changing the curing agent, accelerator, etc., the formula of epoxy resin can be varied to have a variety of properties to meet various requirements. This is one of the advantages of epoxy resin packaging materials.

Epoxy resin can obtain higher thermal conductivity and insulation through appropriate addition and modification, so it can be used in electronic devices. Epoxy resin has strong bonding force, and it will also become brittle due to aging during use, which is related to the low toughness of epoxy resin and the structural changes during aging. Various modifications to epoxy resin can improve its aging resistance to a certain extent.

Epoxy resin encapsulation of solar cell modules has a simple process and low material cost, and is widely used in the packaging of small modules.

What is organic silicone encapsulation material?

Organic silicone is a kind of encapsulation material with a special structure, which has many properties of both inorganic and organic materials, such as high temperature resistance, low temperature resistance, aging resistance, oxidation resistance, electrical insulation, hydrophobicity, etc.

Silicone is an elastomer that can deform under the action of external force and return to its original shape after the external force is removed.

Silicone gel is divided into neutral and acidic types. Acidic silicone gel will corrode silicon wafers, so neutral silicone gel is generally used. Silicone gel has strong adhesion to inorganic non-metallic materials such as glass and ceramics, and also has strong adhesion to metals, so it is widely used in the installation industry.

Taking advantage of the adhesiveness, adhesion and transparency of silicone, it can also be used as surface encapsulation, sealant, etc.

Silicone material is a transparent material with a light transmittance of more than 90%. It is a widely used film material. Silicone has the characteristics of low-temperature curing, which can facilitate surface coating, etc.

If you want to get more information. pls follow buyit or What’s app: 008613808405352