Photovoltaic丨What are the common faults of photovoltaic inverters?

What are the operating statuses of photovoltaic inverters?

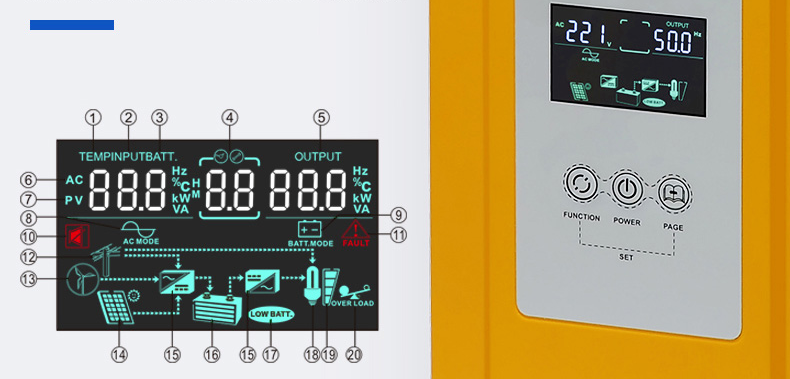

Photovoltaic power station inverters have five operating states: waiting, self-test, normal power generation, fault and shutdown.

After the photovoltaic power transmission starts, the display will show “Waiting”. If the photovoltaic system is normal and there is mains power, the display will show “Self-check 30S” later, and the machine will start self-check. After the self-check is completed, the display will show “Connected to the grid for power generation”.

If there is a problem with the photovoltaic system, the machine will report an error message with a “fault” message.

What are the starting conditions for photovoltaic inverters?

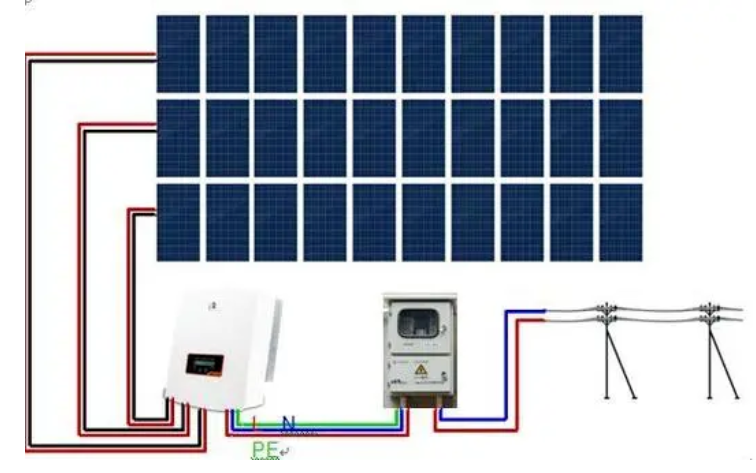

The function of the photovoltaic inverter is to convert the DC power generated by the photovoltaic modules into AC power. The starting condition of the inverter is that the DC switch of the inverter is in the ON state.

At the same time, sufficient lighting is required to ensure that the DC input voltage is greater than the inverter starting voltage and less than the maximum DC input voltage. The total short-circuit current of the DC power is less than the maximum short-circuit current of the inverter, so that the inverter can operate normally.

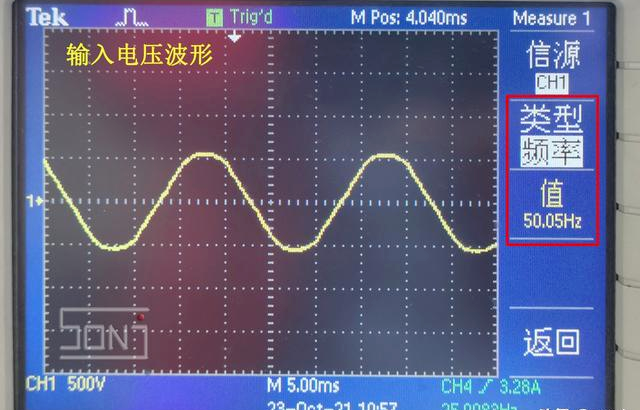

It also requires the grid to operate properly, that is, the grid voltage and frequency remain within a specific range.

What are the reasons why a photovoltaic inverter stops working?

The reason why the photovoltaic inverter stops working may be because the DC switch is in the OFF state, or it may be because the sunlight is weakened, causing the DC input voltage of the photovoltaic module to not meet the inverter starting voltage.

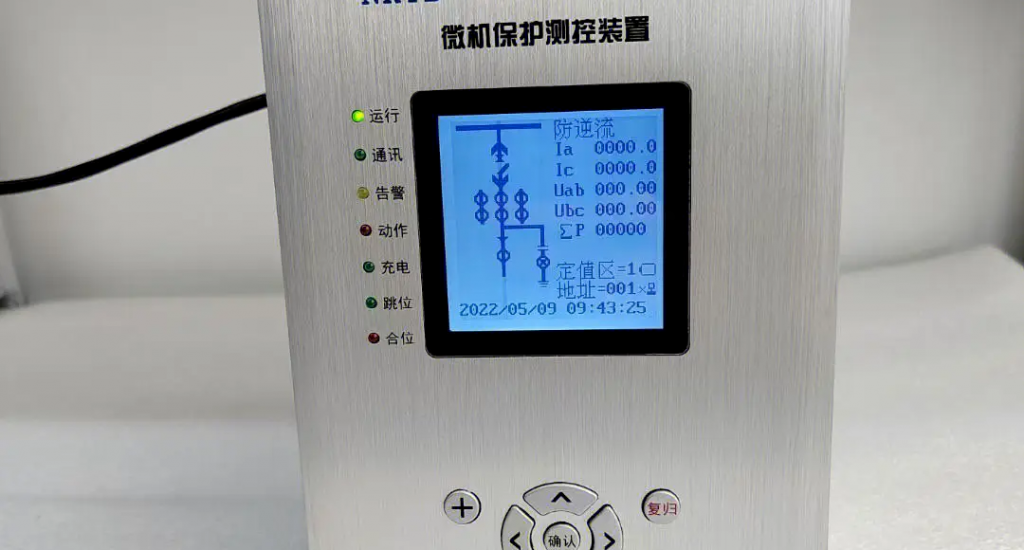

In addition, the inverter is equipped with an anti-backflow device. When the AC side circuit breaker is disconnected and the power grid is disconnected or lost, the inverter will stop working.

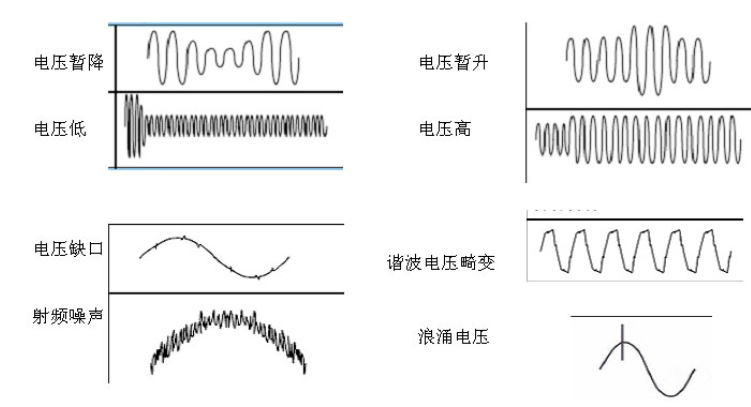

When the inverter detects an abnormality in the grid voltage or frequency, that is, it exceeds the operating range required by safety regulations, it will also stop working.

What is PV inverter full load?

The full load of the photovoltaic inverter means that the DC input power reaches the rated value. That is, the output power of the solar cell array reaches the rated DC input power value of the photovoltaic inverter.

Due to the characteristics of solar cells, their output power is determined by the load. Therefore, even if the rated power of the photovoltaic array far exceeds the rated input power of the inverter, it will not necessarily cause damage to the inverter. However, attention should be paid to its open circuit voltage and maximum The current at the power point cannot exceed the allowable value corresponding to the inverter. Some inverters allow 10% excess usage, and there will be power loss at this time.

What is inverter over-temperature protection?

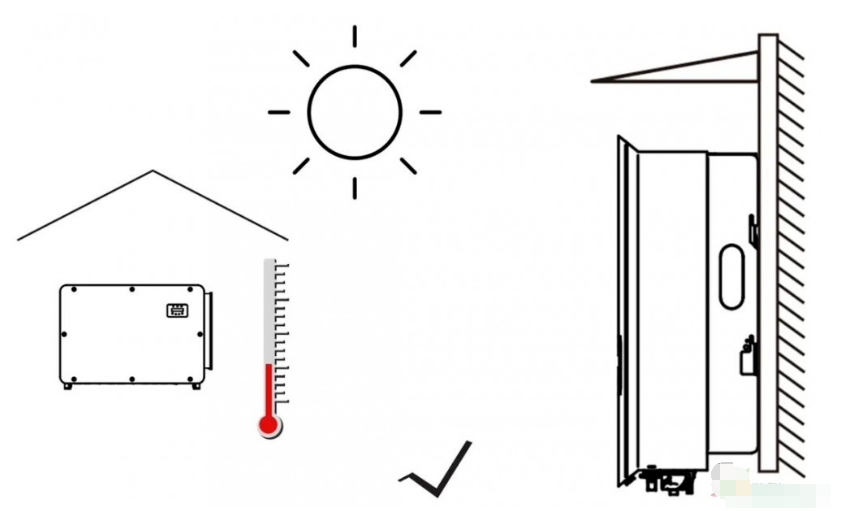

Inverter over-temperature protection means that when the temperature inside the equipment rises to a specified value, the inverter can detect an abnormality and reduce the output power or stop the inverter operation.

The power generation of photovoltaic power stations is closely related to the inverter. In the hot summer weather, the heat dissipation of the inverter is an issue that photovoltaic people easily overlook. The power loss that may be caused by the heat dissipation problem, and even the over-temperature protection (load reduction) of the machine, really affects the power generation.

Long-term direct sunlight will damage the life of the inverter components. Direct sunlight has a direct relationship with the temperature in the cavity, affects the life of components such as capacitors, and accelerates the aging of the equipment.

When the inverter has over-temperature protection, you first need to check whether the ambient temperature is within the operating range of the inverter. At the same time, check whether the installation space in the cabinet is sufficient, whether the fan in the cabinet is normal, and whether the ventilation volume can meet the requirements of the inverter. Limit the inverter output current, or reduce the current. At the same time, when the power is off, the dust from the frequency converter is blown out.

If the persistent over-temperature protection cannot solve the problem, it is recommended to call a professional for repair.

What is the inverter grid voltage exceeding the limit?

The grid-connected inverter of a photovoltaic power station must work within the specified grid voltage range. Grid voltage over-limit means that when the inverter voltage value exceeds the safety requirements, the inverter must trip and stop working to ensure that the equipment and Operator safety.

Because the cable between the inverter and the grid connection point is too thin, too long, or tangled, the voltage on the AC terminal side of the inverter is too high when the grid voltage is normal. Use a multimeter to detect the output voltage of the inverter and the voltage of the grid connection point respectively. If the output voltage of the inverter is much greater than the voltage of the grid connection point, it means that the line loss is large. It is recommended to replace the cable or modify the default safety voltage range of the inverter after obtaining permission from the power grid company.

What should I do if the inverter PV voltage is high?

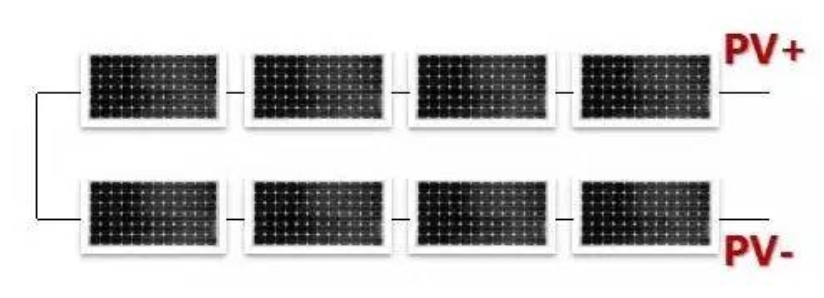

The inverter displays high PV voltage usually because there are too many modules connected in series, causing the voltage to exceed the inverter’s voltage alarm.

When encountering this problem, you need to use the temperature characteristics of the component that the lower the temperature, the higher the voltage, to adjust the voltage after the string.

The input voltage range of single-phase string inverter is 100-500V, and the recommended voltage after stringing is between 350-400V.

The input voltage range of the three-phase string inverter is 250-800V, and it is recommended that the voltage after the string is between 600-650V.

In this voltage range, the inverter has high efficiency and can generate electricity even when the irradiance is low in the morning and evening. At the same time, the voltage will not exceed the upper limit of the inverter voltage, causing an alarm and shutdown.

What should I do if the photovoltaic inverter screen does not display any information?

The photovoltaic inverter LCD is powered by DC. The main reason why the inverter screen does not display is that there is no DC input

The cause may be insufficient component voltage. Or one of the connectors of the component is not connected properly and a short circuit may occur. At the same time, you need to check whether the DC switch is closed and whether the PV input terminals are connected reversely.

Use a multimeter to measure the DC input voltage of the inverter. When the voltage is normal, the total voltage is the sum of the voltages of each component. If there is no voltage, check whether the DC switch, wiring terminals, cable joints, components, etc. are normal. If there are multiple components, they must be connected separately for testing.

If the inverter has been used for a period of time and no cause is found, it may be that the inverter hardware circuit is faulty. You can contact the manufacturer for after-sales service.

What should I do if the insulation resistance of the photovoltaic inverter to ground is too low in summer?

In the rainy weather in summer, the casing and other moisture can easily cause water to enter. Improper AC wiring may also cause water to enter some machines, and the component waterproof box may also malfunction.

When the inverter encounters these problems, the most common error message is “insulation impedance to ground is too low.” The DC cable and grounding conditions of the components need to be checked on-site.

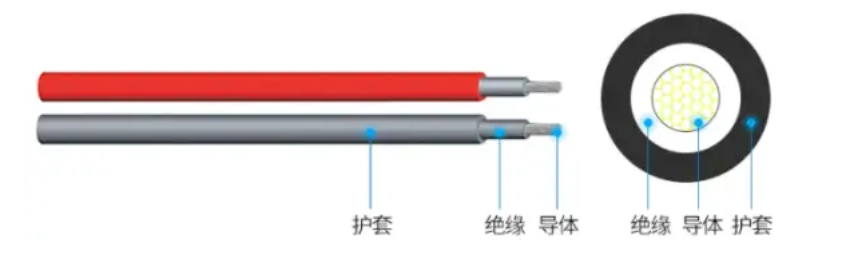

First you need to check the DC cable, component side grounding and bushing water ingress. Most panel insulation impedance problems are caused by damaged DC cables, including cables between modules and cables between modules and inverters, especially cables in corners and cables laid in the open air without pipes. check carefully.

In many project sites, DC lines are often in contact with module panels. Over time, the aging of the DC line outer skin may cause a certain degree of corrosion on the back of the module. Avoid direct contact of cables with the back of components; use cables with higher anti-corrosion and anti-aging levels.

If the photovoltaic system is not well grounded, it will also affect the inverter’s ability to correctly detect the insulation resistance value of the module to the ground. Problems on site include:

The component bracket is grounded, the inverter side is grounded, and the distribution box side is grounded.

For more photovoltaic related knowledge, pls contact buyit company what’s app: 008613808405352

-

liFePO4 Battery 51.2V 100AH Warranty 5 years cycle life>6000

liFePO4 Battery 51.2V 100AH Warranty 5 years cycle life>6000 -

IP21 PV INVERTER/SINGLE PHASE- 4KW / 6KW/ 10KW/ 15KW

IP21 PV INVERTER/SINGLE PHASE- 4KW / 6KW/ 10KW/ 15KW -

IP65 Hybrid solar inverter /single phase/ 6kw/8kw/10kw/12kw

IP65 Hybrid solar inverter /single phase/ 6kw/8kw/10kw/12kw -

11KW 48V Off grid Solar Inverter with parallel function

11KW 48V Off grid Solar Inverter with parallel function -

1.5kw/2.5kw/3.5kw off grid inverter 230VDC PV: 30-500V

1.5kw/2.5kw/3.5kw off grid inverter 230VDC PV: 30-500V -

1p 1.5p 2p 3p Inverter Cool & Heat Split Solar Air Conditioner

1p 1.5p 2p 3p Inverter Cool & Heat Split Solar Air Conditioner -

Wallbox EV Charger Home Use AC Electric Vehicle Charger 7kw 11kw 22kw Portable EV Charging Station

Wallbox EV Charger Home Use AC Electric Vehicle Charger 7kw 11kw 22kw Portable EV Charging Station -

CTS CCS CHAdeMO GBT Road Rescue DC Fast Charging Station 20KW 60kW Mobile EV charging station with lifepo4 battery

CTS CCS CHAdeMO GBT Road Rescue DC Fast Charging Station 20KW 60kW Mobile EV charging station with lifepo4 battery -

Energy Charging Pile 60kw 120kw 180kw 240kw DC OCPP App Control Fast Car EV Charger Station

Energy Charging Pile 60kw 120kw 180kw 240kw DC OCPP App Control Fast Car EV Charger Station